Flexibility and Stability: Dimensions of Efficiency

Even when components change, your FlexiBowl® stays the same

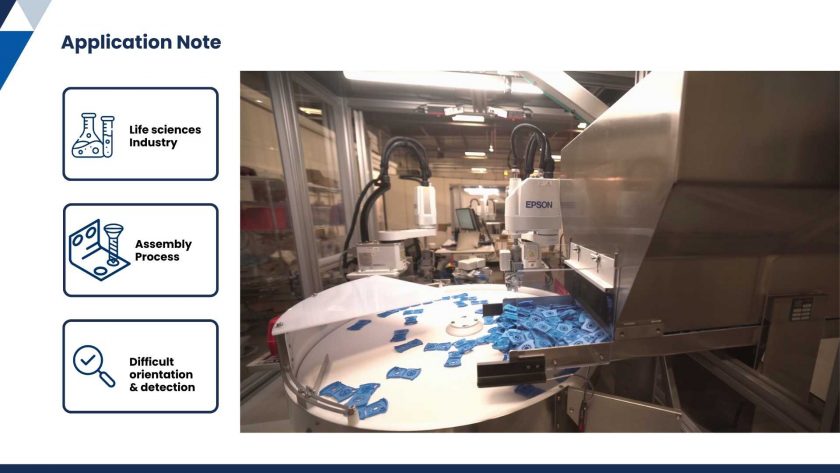

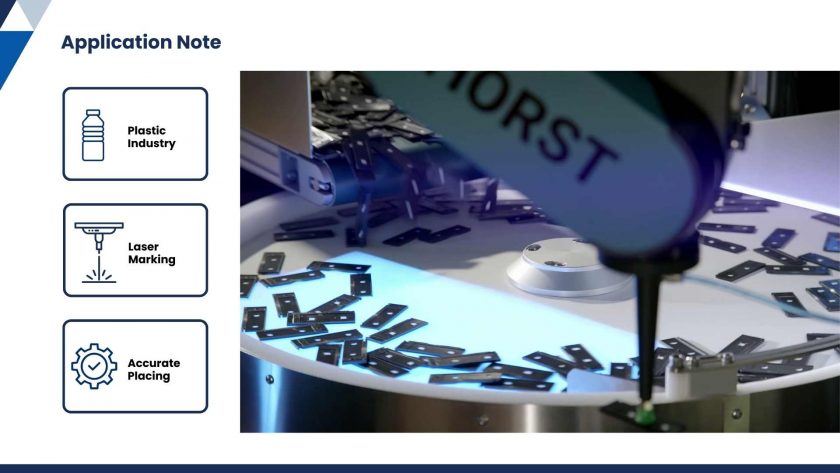

Application Sectors

Application Freedom

Flexibility that embraces change

Modern production requires constant adaptability, with components and production lines needing to be reconfigured quickly. Our feeding systems and support team help companies face this challenge with dynamic and efficient solutions.

Evolving technology for every sector

We design reliable solutions that can evolve. This is why our systems are chosen by companies across various industries, because they adapt to every specific production requirement, combining stability and reconfigurability.

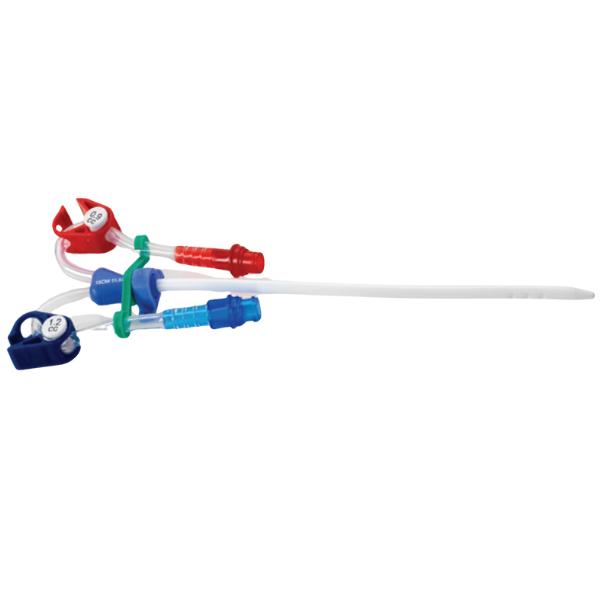

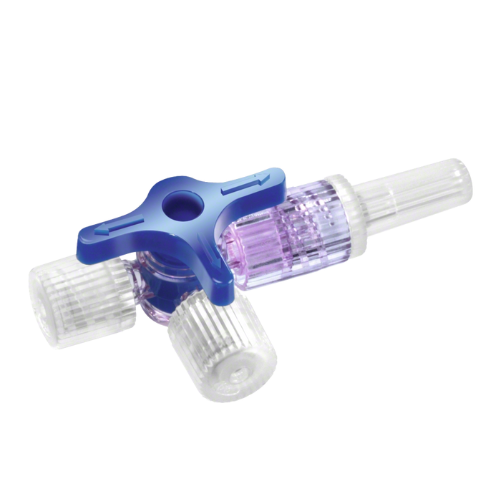

Tailored performances, regardless of shapes

We meet high process and performance requirements, feeding components ranging from 1 to 300 mm and 1 to 300 g, regardless of their geometry, surface, or material.

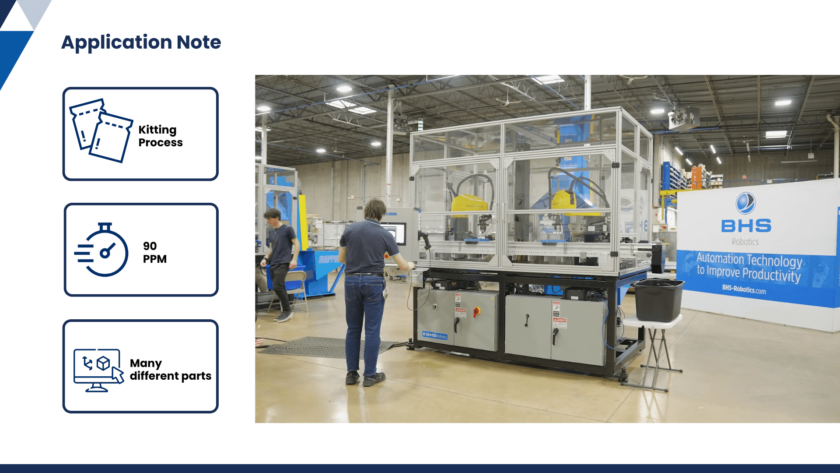

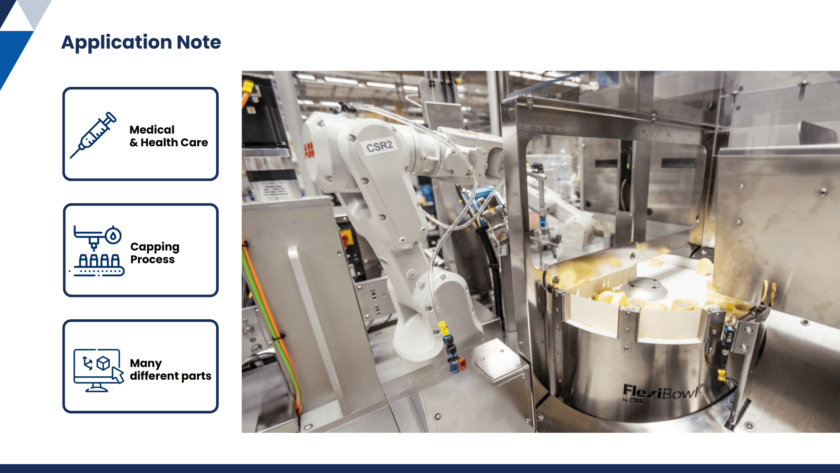

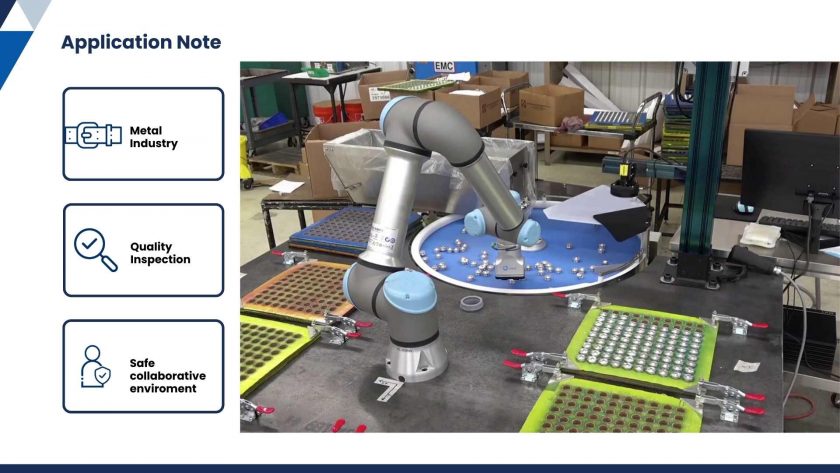

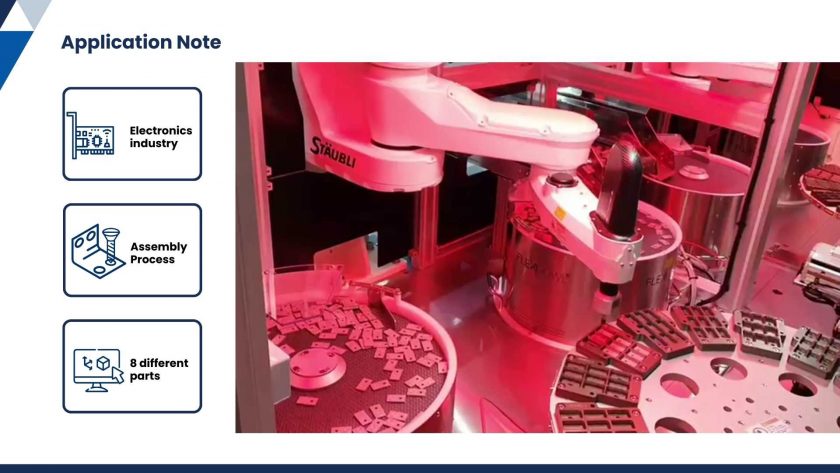

Our Projects

Explore some of our recent projects and discover how our automation solutions have transformed our clients' production processes.